SAVE OUR BEAUTIFUL PLANET

At the heart of innovation and sustainability, our journey began with a vision to transform the polymer industry.

REDUCE

REUSE

RECYCLE

SAVE EARTH

Join Over 200k People Making a Difference

Sustainability in Polymer Manufacturing

In a polymer manufacturing company, sustainability focuses on reducing environmental impact and promoting responsible use of resources. By integrating sustainable practices, the industry can contribute to a more eco-friendly and efficient production process.

- Eco-Friendly Materials

- Energy Efficiency

- Waste Management

- Water Conservation

- Green Chemistry

- Lifecycle Design

- Sustainable Sourcing

- Pollution Control

Volunteer! There Are So Many Ways to Lend a Helping Hand

Government Acts Supporting Sustainability

Government acts and regulations play a crucial role in promoting sustainability within the polymer manufacturing industry by setting standards and encouraging eco-friendly practices.

- Environment Protection Act, 1986

- Plastic Waste Management Rules, 2016

- Energy Conservation Act, 2001

- Hazardous Wastes Management Rules, 2016

- Extended Producer Responsibility (EPR)

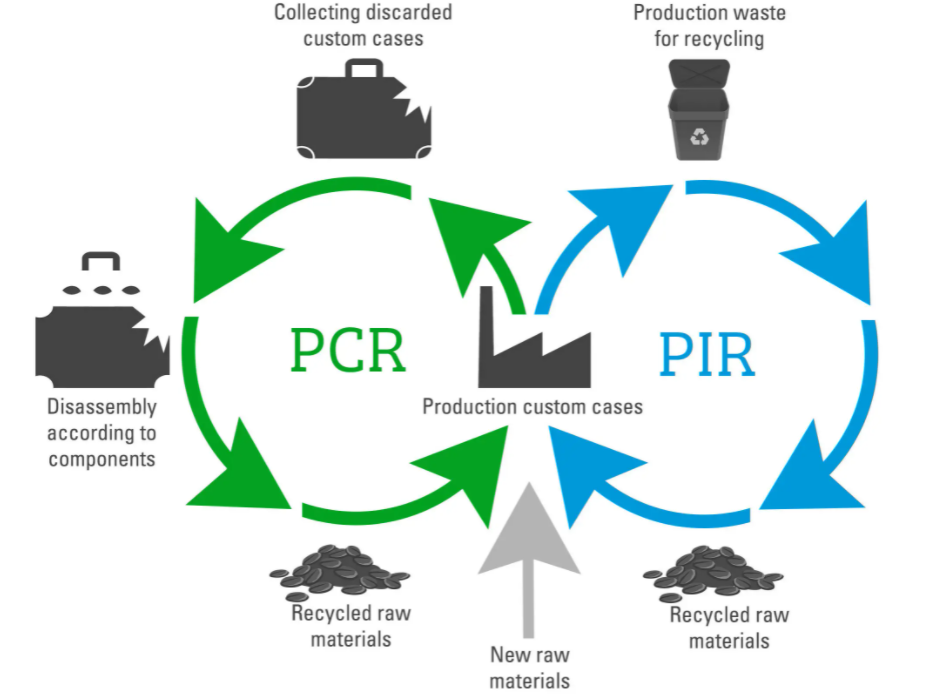

METHODS OF RECYCLING

PCR (Post-Consumer Recycled) Method:

- Source Material: Collected from end-users or consumers after product use (e.g., plastic bottles, containers).

- Collection: Involves curbside recycling programs, drop-off centers, and reverse logistics.

- Sorting: Materials are sorted by type (e.g., PET, HDPE) to ensure high-quality recyclate.

- Cleaning: Thorough cleaning of collected materials to remove contaminants like labels, food, or chemicals.

- Shredding: The cleaned plastics are shredded into small flakes or pellets.

- Melt Processing: The shredded materials are melted and reformed into granules or pellets for reuse in manufacturing new products.

- End Products: Primarily used for non-food contact applications or downcycled into lower-grade products (e.g., packaging, textiles).

- Sustainability Impact: Reduces reliance on virgin plastic, decreases landfill waste, and lowers carbon emissions.

PIR (Post-Industrial Recycled) Method:

- Source Material: Comes from industrial waste during the manufacturing process (e.g., scrap material, off-cuts).

- Collection: Gathered directly from factories or production facilities as part of their by-product management.

- Sorting: Materials are sorted by type to maintain quality and consistency.

- Processing: The waste is often in better condition (since it hasn’t been used by consumers), requiring less intensive cleaning and processing.

- Reintegration: The recycled material is reintegrated directly into the production cycle, often blended with virgin polymers to maintain desired material properties.

- End Products: Used in various applications, such as packaging, automotive parts, or construction materials.

- Sustainability Impact: Helps reduce industrial waste and improves the circularity of manufacturing processes.

METHODS OF SUSTAINABILITY

DOING PLANTATIONS

SAVING WATER CONSERVATION

GREEN ENERGY CONSERVATION

SOLAR ENERGY CONSERVATION

WIND ENERGY CONSERVATION